ISO 9001:2015

Quality Control

We at Charvi Extrusion, manufactures quality Copper Alloy Extruded Rods and Sections are committed to:

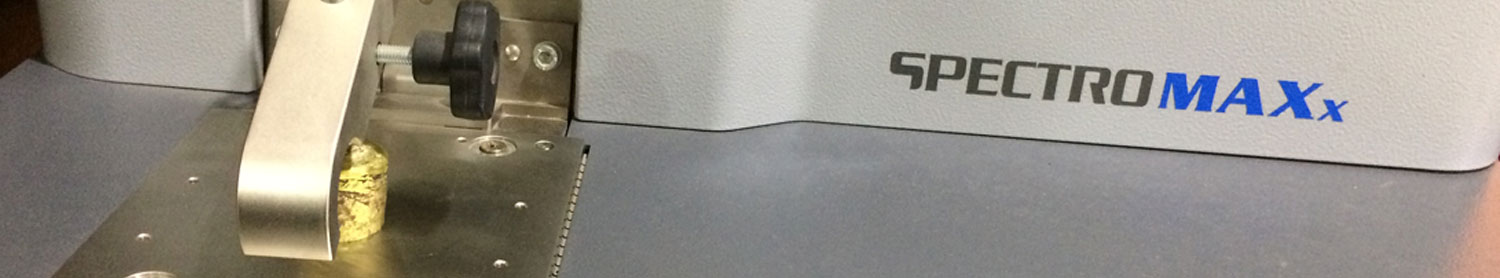

We have the title of "ISO 9001:2008 Certified Company" since the first year of our working to our credit, which reflects our strong quality focus attitude. Testing of Copper Alloys through Electro Photo Spectrometer, not only ensure exacting Chemical Composition of Copper Alloys, but instills in us a confidence to guarantee quality. The task begins with the procurement of proper raw material and ends with timely delivery of material to the customer as per their stipulated specification. Offering R&D, design, development and manufacturing services for the high-tech industry, our management staff have excellent technical experience and marketing capabilities.

The strict quality control is maintained through out the production cycle i.e. starting from raw material till the finished good that is ready for dispatch. In order to achieve high standards of quality constantly as per demand of our valued buyers, we strictly inspect all our process involved in the production of the product.

At Charvi Extrusion, we are well equipped with high efficiency Quality Testing Machines like modernized Spectromaxx, Tensile Strength Checker, Profile Projector, Hardness Testing Machine and a wide array of TQM systems. After passing all arrays of rigorous testing these machines ensure best possible quality check for our esteem customers.

Test Equipment and Facilities:

We consider each stage of the production process as critical and monitor it with precision. From temperature controls while the online spectro-analysed metal is being poured to monitoring the pre-heating and soaking of billets, and fracture testing of each and every copper alloys extrusion we use stringent control methods to ensure, quality, compliance and safety.

Every state of the production cycle is considered important and thus closely monitored, be it pouring of online spectro-analysed metal at right temperature or pre-heating / soaking of billets, to fracture testing of each and every copper alloys extrusion.